Fluffy and Bo's New Cage

Background

Fluffy and Bo previously resided in two separate cages on a baker's rack. Fluffy was in a 50 gallon tank on the top shelf. Bo was in a 40 gallon tank on the lower shelf. This is the third cage he's had since we've had him. When he was small he was in a 30 gallon tank and he was so small it would be hard to find him. As he grew we had to move him to the 50 gallon tank which he then outgrew in about a year and now he's so big that we've build this custom habitat for him and Bo.

Photo of Fluffy in his Old Habitat

He's grown quite a bit since this photo was taken.

The tank Bo was in was too narrow for his size as well. If he wanted to turn around he would have to fold his body to be able to do so. For comparison his old tank was about as deep as his pink hiding house that he's pictured on top of in his now home to give and idea for the scale of the difference just in terms of depth from his hold habitat versus his new habitat.

Bo on Top of His Pink Hide

His old cage was only as deep as the pink house is wide.

Design Process

Before you construct anything it's a good idea to come up with a solid design. We've looked at several large habitats that you can buy on the internet ranging from $600 on up. We looked at several of these products before we began to plan our design. We knew that we wanted to provide an environment for two animals both of which are semi desert dwellers but Fluffy who happens to live in a semi desert/forest savannah kind of an environment. So we knew that Fluffy would prefer to hang out high and sit on branches while Bo the bearded dragon would prefer to chill out on the floor of the habitat. Bo's physiology requires heat and light. Where fluffy requires water for drinking and bathing and branches to climb and a gradient of hot and cold in his environment so he don't over heat or freeze.

Knowing this we realized that we would need to synthesize an environment that could provide for these requirements.

Our first consideration was size, the main reason for building this new enclosure was to allow both animals a larger habitat to live in, they out grew their old enclosures. We wanted the new enclosure to be large possibly 6 feet tall by 4 feet wide by 2 or 3 feet deep.

Secondly we had to consider logistics and how to practically make a suitable environment that was semi-portable in the event we would have to move some day and for consideration of the fact that we were building the enclosure on our garage and that it would have to be carried up three stories to our bedroom. The key to doing so would be to first make it small enough to fit through doors, up stairs, around corners and light enough so that it could be lifted with a two-wheeler moving cart. This alone informed several decisions we had to make about what kinds of materials to use. We were either going to use wood or metal to build the frame, metal was nice because you can use relatively thin pieces to construct a frame on the down side it's difficult to work with it must be cut and welded and it's more expensive to work with.

So rather than construct the frame of the habitat from metal we decided to use 2 x 3 wood to build the frame. 2 x 3 wood was the smallest wood we could work with, any smaller like 2 x 2 or 1 x 1 and the frame would be too weak to support the weight of the roof of the enclosure, also any smaller than 2 x 3 and the pieces you work with tend to not be straight or to bend in an awkward way.

Another thing we had to decide on what kind of material to use for the front of the habitat. We want to be able to see through inside the habitat. We considered our options glass plexiglass or a screen material. Regular glass would be too dangerous to risk shattering, it's difficult to mount in place and it's extremely heavy and it can be easily scratched. We strongly considered plexiglass, the main reason we didn't go with it was because it's expensive, difficult to cut without cracking, it scratches easy. The advantage to using any kind of glass material is that it insulates the heat in the habitat. When you have a well insulated habitat you can use less heating elements and/or heat lamps in the habitat. We ended up using a screen material. We didn't want to just choose any screen material. I would strongly caution against using any screen material that is composed of metal or wire as most are. We went to Lowe's and they had a screen product specifically for cats who scratch screens, it's more of a plastic or venal material. I would be concerned that if the screen material were metal a bur or a stray wire could scratch or cut the inhabitants. Fluffy enjoys climbing up on the screen and basking near the heating lamps. It's kind of strange to see a lizard floating in mid air, that's what it looks like sometimes. He's not light and his claws are sharp, the screen material that we used is a good product it supports his weight and it has yet to break under his weight.

Another thing that we wanted to do was to have the walls simulate rock. Because the walls were made up of plywood we ended up buying large sheets of styrofoam cut them to size, glued them to the walls, covered them with a thin layer of grout to add texture, several layers of non-toxic acrylic paint to simulate depth and the color of rock and a non-toxic sealant like moge poge. The foam has an added benefit of providing insulation for the heat lamps to keep the habitat warm.

Construction Process

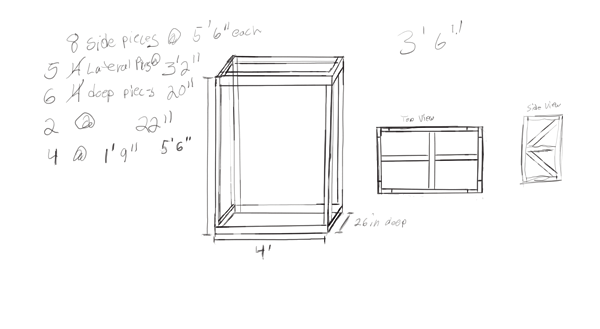

As I was saying before beginning construction you must do research to formulate a concrete design. My partner has a little experience with woodworking so he did the rough design and built the cage for me. This is the sketch he made in preparation for getting the wood and in preparation for construction.

Our Initial Sketch for the Frame

By sketching out this design it helped to calculate how many 2 x 3 inch pieces of wood we needed, they came in 8 foot lengths.

Once we went to Lowe's and bought the materials he took them home and in the garage he cut the lengths for the frame and tacked them together with his air nailer.

Construction Step 1 Cut Wood to Length and Tack it Together, Clamps Help a lot!

Construction Step 2 Reinforce the Joints with Struts, tack the pieces together with nails

Construction Step 3 Attach Cross Braces

Use an air nailer, it speeds up the process tremendously and gives a nice clean look to the final product

Construction Step 5 Join Sides Together

Construction Step 6 Reinforce the Joints with Metal Struts

Now the Frame is Put Together with the reinforcing struts it's very strong too.

Roughly Assembled

I've omitted a few steps in between. But this is assembled with plywood on the bottom and sides and another layer of inch and a half thick layer of insulating foam and grout. The foam is layered to look like several layers of slate. There are also doors cut on either sides with a long hinge to allow access to the inside of the cage from either side of the cage. Once the screen is on the front of this you will not be able to access the inside of the cage unless you have doors.

Finishing Processes

This is with more of the highlighting done and some of the layers of paint coming together, there are a lot of hues of blues and greens to bring out the texture.

Finally it's important to apply a layer of sealant. We used moge poge, which looks very glossy when it goes on but after it dries it's very matte.

This is what the final product looks like with the top, lights, screen bedding and props in place:

The final thing was light enough for my partner to get it upstairs on a two wheeler.

Just so you know you should put bigger thicker logs in the enclosure and I bet bo would climb onto them my beardie loves climbing up higher towards the heat source

ReplyDelete